Filtration - Product List

- Photo :

- Name : FILTER CLOTH

- Code :

- Description :

As filter cloth manufacturers and filter cloth suppliers,Strongard Corp takes special care to review the client’s process in designing filter cloth tailored for their specific needs. Our automatic manufacturing equipment ensures reliable, precise products that perform consistently. The result is cost-effective filter operation with lower labor costs and a process stream that meets your goals.

As filter cloth designers, moreover, we offer a full range of woven and felted synthetic filter cloth, including woven constructions of monofilament, spun, multifilament, combination yarns, and needle felts with various surface finishes.Weave designs, fiber choice, and special finishing techniques are used to enhance the filtration and cake release characteristics of our materials.

Filter cloth yarns have specific properties, which are used when designing our products.

Defining The Diameter Of Fibre And Mesh Size

The fibre diameter, or the mesh size , determines the mechanical resiatance and flow rate.

Strongard Corporation uses a whole range of fibre diameters from 0.5 micron .- Filter Cloth Weave Patterns

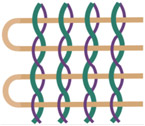

- Filter Press Cloth Weaves

Plain Weave Twill Weave Basket Weave Leano Weave Satin Weave

Material selection for our designs is based upon your application and specific requirements. Process for designing, measuring and creating your filter cloth ensures a superior product that will stand the test of time.Drawing of Filter Cloth

Filter Press Cloth ConstructionConstruction of filter cloth assemblies plays an equally important role to the fabric design in achieving optimum performance. A precise fit assures peak performance.

Methods of Attachment

There are various methods for fastening cloth. Attachments may be stitched, welded or machine assembled to provide durable constructions. Peg eyelets, cloth castellation & rod suspension are used to carry the cake weight. Side tie eyelets & reinforced holes, keep the cloth flat and positioned correctly.Velcro

Velcro provides a lapping joint, which has superior strength and keeps the cloth aligned correctly throughout the many months of operational life. This attachment is easily repositioned or released for plate inspection or adjustment.Edge Reinforcing (Banding)

Reinforcing around the filter plate sealing surface and over the stay bosses will increase the mechanical strength of the cloth. Strongard Corp banding material is specifically manufactured with high tensile strength and stability for this application.Finishing & Assembly

Cloth is assembled by stitching, automatic welding, and joining machines. Synthetic rubber sealant edge treatments are precisely applied using custom machinery.Picture of Filter Cloth / Filter Component

- Details

- Enquiry

- Photo :

- Name : FILTER BAG

- Code :

- Description : The convenience and economy of liquid bag filtration is now feasible for filtration applications that previously required other more expensive systems. Because demanding or critical applications can be complex, is available to perform a no-obligation analysis of your process.

- Details

- Enquiry

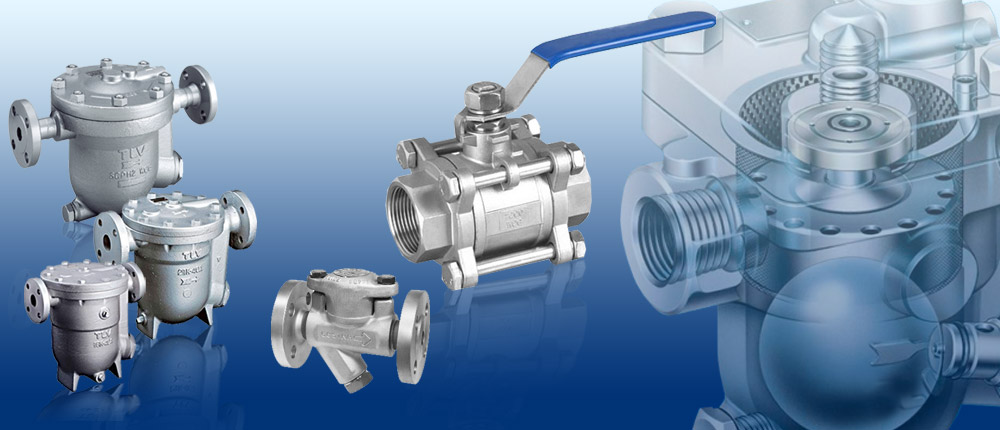

- Photo :

- Name : FILTER BAG HOUSING & CARTRIDGE

- Code :

- Description : Bag Filter and Cartridge Filter proved to be most effective in following applications due likes handling and cost effective as compared to easy to other traditional system filter press & self cleaning system.

- Details

- Enquiry

- Photo :

- Name : Power Transmission

- Code :

- Description : Stainless steel gear units keep things moving wherever machines and systems are subject to particularly intensive cleaning. Regardless of whether the gear units are used for materials handling, intralogistics or hygienic applications, their hygienic properties, long operating life...

- Details

- Enquiry

- Photo :

- Name : Filtration Products

- Code :

- Description : Filtration is used to separate and fluid in a suspension, where the fluid can be a liquid, a gas or supercritical fluid. Depending on the application , either one or both of the components may be isolated.

- Details

- Enquiry